PV Monitoring as a Service: An Added Value for Customers?

by Vivian Bullinger | 07.12.2020

We take a closer look at this question from different perspectives. What solutions does PV monitoring offer? What are the benefits for the plant owner and the installer? What does the future look like in this area?

What is PV Monitoring?

From the beginning, what is PV monitoring? A PV system generates electricity, which in turn is fed into the grid or consumed directly. The monitoring system now monitors whether the calculated electricity is actually generated or whether losses occur. If an error occurs, i.e. less PV electricity is generated than possible, the system reports this problem. This form of loss in electricity generation is also known as yield loss. Whether PV system owners, installers, EPCs, portal operators, investors, asset managers, or insurance companies, all expect photovoltaic systems that are error-free, and without yield loss. However, how can these expectations be met? A well thought-out Operation & Maintenance (O&M) solution and a PV system monitoring service provide the answers.

What is behind O&M in PV Monitoring?

Operation & Maintenance is a process designed to help PV systems achieve the highest possible efficiency. It can start at the planning or financing stage of a PV plant and extends beyond the operating period. During the operating period, the aim is to keep the number of faults in PV systems as low as possible and to rectify any faults quickly. For example, if a problem occurs at a plant, the PV monitoring system detects the error. If necessary, it forwards this error message so that it can be rectified promptly. Thus, O&M ensures that the downtime of a plant is minimized and the runtime of a plant is maximized.

Advantages of External PV System Support

Forwarding takes place when, for example, PV monitoring is required, but the operator of the plant does not want to make the effort for it himself. In this case, he passes on the monitoring to a third party, so-called external portal operator. The job of the external portal operator is taken over at Solare Datensysteme by the Solar-Log™ WEB-4U team under the leadership of Dirk Gabel, Manager Operations. Together with Christian Schack, Marcel Herzmann, and Manuel Badalucco, he forms the core team in plant monitoring. With the Solar-Log WEB Enerest™ platform and the Solar-Log™ WEB-4U Service, they have almost 1200 PV plants under control. The spectrum ranges from the nearly 3 kWp domestic plant to the 2 MW industrial plant.

Fast Information Flow & Analysis of Error Messages.

The experts of the WEB-4U team take over the monitoring of PV systems for portal operators. They analyze and evaluate all incoming error messages. Part of the service is the proactive information flow between experts and portal operators. If the worst comes to the worst, they immediately initiate measures to solve the problem. This includes a comprehensive information package, which contains, for example, information and details about the problem in question, as well as recommendations with a view to solving it. This makes the installers' work easier and gives them more time for their core tasks.

Who benefits from the service besides the portal operator?

- The provision of detailed information and empirical values makes potential improvements to PV systems clear, for example. This in turn leads to improved plant performance. Plant owners therefore benefit doubly from professional monitoring: with more service, as problems with the plant are rectified promptly, and with more security, as they know that the plant is monitored at all times.

- Transparent reporting is important for investors. Continuous monitoring and logging of plant data enables straightforward reporting.

- In the event of a claim, it can be helpful to submit logs to insurance companies to expedite the settlement process. In addition, comprehensive forecast values, for example, help asset managers to select a suitable time for maintenance work.

- Qualified and neutral PV system monitoring plays a crucial role in the O&M process. Without it, all further steps in the course of troubleshooting cannot be taken - or a problem would only be noticed at a late stage.

Future Steps for Improved PV Monitoring

Holger Schroth, Chief Product Officer at Solare Datensysteme GmbH, knows the PV industry very well and knows what developments would support installers and system managers. Mr. Schroth gives us a little glimpse into the PV future and what innovations it might bring:

Automated Fault Detection

One of the most interesting areas is certainly automated error detection. The new Solar-Log WEB Enerest™ 4 already offers a context-related error analysis that provides the plant operator/ supervisor with all the necessary data. With this information, troubleshooting is already faster and easier.

In the future, this area certainly offers a lot of potential. For example, it is conceivable that in-depth data analysis could be used to identify and localize fault patterns even more quickly. This intelligent analysis can not only reflect a concrete error image, but also provide the plant operator with targeted options for action to correct the error.

In practice, this could then be applied as follows: the monitoring system reports a communication problem between the data logger, the PV plant, and the portal. The portal then automatically triggers a test routine and checks various sections in the communication chain. The result is passed on to the user and, depending on the location of the error, the user is given options for action to correct the error. The system thus recognizes that a connection is available up to the gateway in the PV plant and passes this information on to the user. This eliminates the need for time-consuming troubleshooting along the entire communication chain.

These and other tools are conceivable and offer the O&M partner the possibility of saving time in troubleshooting, which in turn increases the operating times of the plant and ensures its profitability.

Direct Spare Parts Ordering

Another area with development potential is spare parts ordering. Older existing plants in particular often have the problem that the right spare part is only available to a limited extent. This can be seen clearly in the area of modules alone. Here, the performance classes have developed massively in the last five years. If there are now module problems in an older PV system, there are hardly any suitable models available for a possible replacement. Some suppliers have already recognized this and offer products and services for this purpose.

If the necessary component information were available via a suitable interface, the O&M partner could search for the appropriate replacement directly after detecting the fault and have it delivered directly to the PV system. This saves time and minimizes error rates due to manual transmissions. In the end, this again minimizes PV plant downtime and maximizes yield.

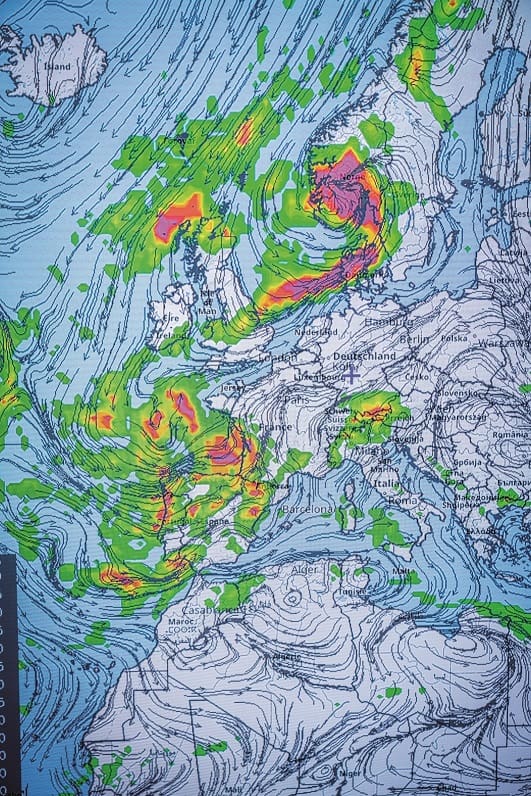

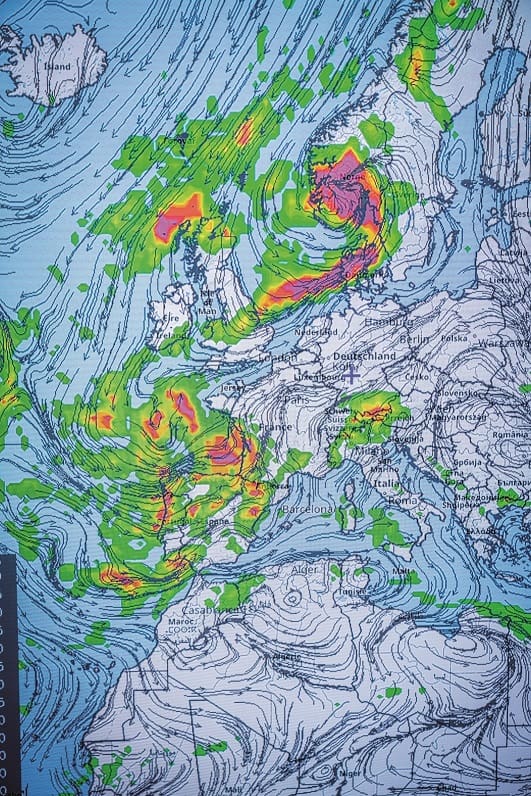

Early Yield Forecasts

Once again, back to the deeper data analysis and thus, for the time being, to the last point of our outlook into the future. This is essentially about detecting faults before they occur. This is certainly the highest level of plant monitoring and thus also the most complex, since a large number of factors are involved here. The greatest work here lies first in the creation of a suitable data structure, in order to be able to examine the quantity of data also specifically for the desired results.

"So far, Solare Datensysteme has always focused on plant monitoring, and this will remain one of our important pillars in the future. Therefore, we are already very busy with these topics and exchange ideas with our customers and partners in the market. We are looking forward to an exciting future with renewable energies," Holger Schroth continues.

Thank you for this exciting outlook.

Back to the overview