Virtual PV plant - bundle data loggers and monitor the total yield

by Vivian Bullinger | 01.06.2023

A virtual PV plant is a combination of several independent PV plants. In this virtual plant, data such as yields and consumption of the individual PV plants are bundled centrally. The current performance of several plants can be seen at a glance and synergies can be exploited.

Advantages of a virtual PV system

- Several Solar-Log™ data loggers can be combined without any restriction on the installed power.

- Larger systems and solar parks in which several Solar-Logs™ are installed can be combined.

- Total generation and consumption are calculated exactly and can be viewed immediately.

- Simple subsequent creation of a virtual PV plant from already created physical data loggers.

- Reuse of a sensor from another PV plant can be used for a virtual plant (similar orientation and inclination required).

Do you want to play the Youtube video?

Yes

No

Configure cookies

Virtual PV plant vs. virtual power plant

Virtual PV plant (VPP) should not be confused with virtual power plant. A virtual power plant is a concatenation of decentralized units in the power grid. The individual units are then coordinated and controlled via a central control system.

Unlike a VPP, a virtual power plant can include a wide variety of generators and storage facilities. In addition to PV plants, these include biogas, wind power, hydropower plants and various electricity storage systems.

In the case of the virtual PV plant, the type of plants is limited to photovoltaics. And there is no central control center in this case either. The focus here is on the evaluation and visibility of important data.

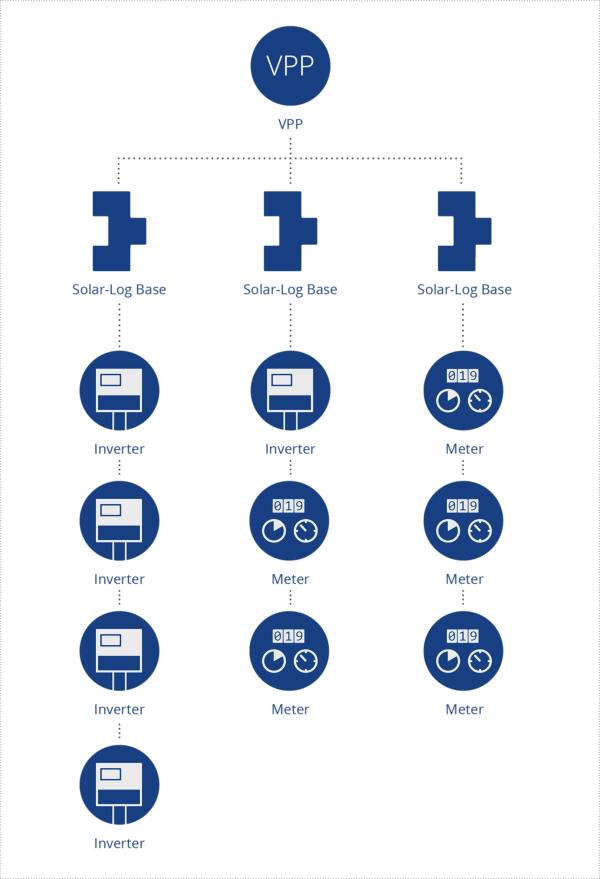

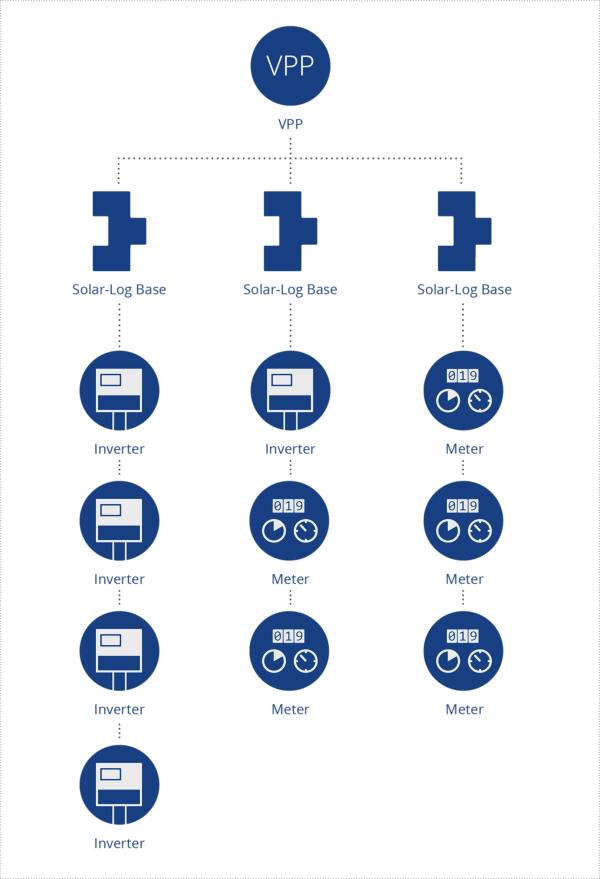

Structure of a virtual PV plant

The structure of a virtual plant can be very different and can be set up individually. The example on the right is a solar park with more than 2 MWp. In such large PV power plants, more than one data logger (such as from Solar-Log™) is usually used for monitoring and energy management.

Previously, the data from the individual data loggers had to be combined in an external system. Now, all components such as inverters and meters from all data loggers are used to calculate the overall balance and displayed in the form of a virtual plant.